Telaire | CO2, Humidity & Dust Sensors

As the world’s first and leading manufacturer of Non-Dispersive Infrared (NDIR) Carbon Dioxide (CO2) Sensors, Telaire has been on the forefront of CO2 sensors technology for over 25 years. Telaire holds 30+ awarded patents in CO2 sensors, including the original automatic calibration algorithm - ABC Logic. In more recent years, Telaire has expanded its product line to include other air quality sensors, including Dust (PM2.5 and PM10) and Relative Humidity (RH) Sensors. Telaire products are used in commercial and residential building ventilation applications, consumer air quality devices for the home, and controlling air quality conditions in automobiles.

- Carbon Dioxide (CO2) Sensors

- Carbon Dioxide (CO2) Transmitters

- Humidity Sensors

- Humidity Transmitters

- Dust Sensors

- Pressure Transmitters

- VOC Sensors

- Accessories

Carbon Dioxide (CO2) Sensor Modules

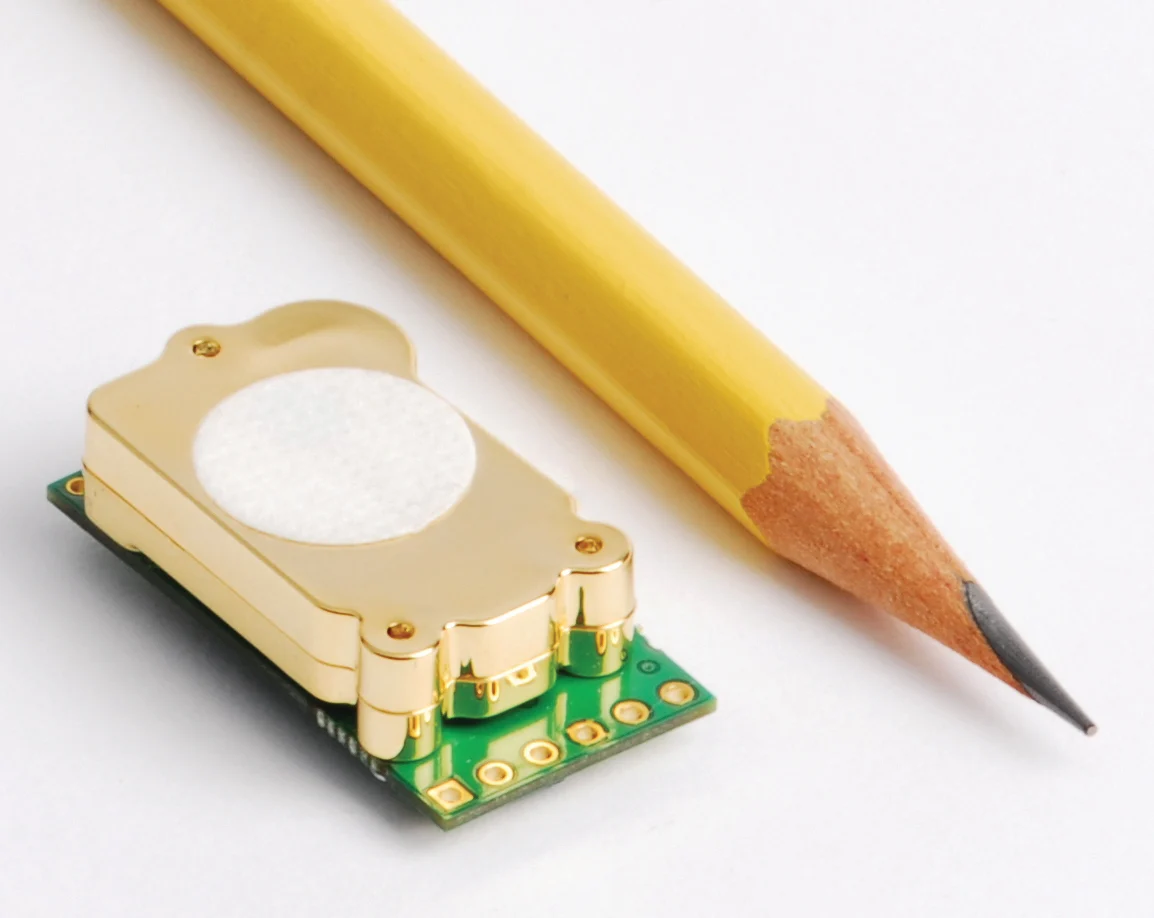

Telaire T6700 Series | Miniature CO2 Sensor Modules

The Telaire T6700 Series of CO2 Sensor Modules is designed for applications that require high accuracy in a compact package. They are ideal for use where CO2 levels need to be measured and controlled for indoor air quality and energy saving applications, such as demand control ventilation.

Telaire T6743 | Internal CO2 Sensor for Automotive Applications

The Telaire T6743 Internal CO2 Sensor is a nondispersive infrared (NDIR) CO2 sensor that implements a single channel diffusion sampling method for automotive HVAC applications, including automatic fresh air control and safety sensing for CO2 refrigerants. Along with the patented ABC Logicâ„¢ lifetime calibration warranty, its low power consumption, compact design and simple product integration, make this an affordable gas sensing solution.

Telaire T6713 Series | CO2 Sensor Modules

Telaire T6713 CO2 Sensor Module is ideal for applications where CO2 levels need to be measured and controlled for indoor air quality and energy saving applications, such as demand control ventilation. All units are factory calibrated to measure CO2 concentration levels up to 5000 ppm.

TELAIRE T6793 | CO2 Sensor Module

Telaire T6793 CO2 Sensor Module is ideal for applications where CO2 levels need to be measured and controlled for indoor air quality and energy saving applications, such as demand control ventilation. All units are factory calibrated to measure CO2 concentration levels up to 5000 ppm.

Telaire T6703 Series | Miniature CO2 Sensor Modules

Telaire T6703 Series of CO2 Modules is ideal for applications where CO2 levels need to be measured to assess indoor air quality, such as residential applications. All units are factory-calibrated to measure CO2 concentration levels up to 5000 ppm.

Telaire T6723 | CO2 Alarm Module

Telaire T6723-8K5 CO2 Alarm Modules are designed for heater applications requiring high limit controls. They are individually factory-calibrated to trigger Alarm Signal at 8500 ppm CO2, Ventilation Warning Signal at 7500 ppm CO2, and Low Battery Warning Signal (for applications using batteries). They are compliant with the latest NF128 LNE test protocol.

Telaire T6613 | CO2 Sensor Module

The Telaire T6613 is a small, compact CO2 Sensor Module designed to meet the volume, cost, and delivery expectations of Original Equipment Manufacturers (OEMs). The module is ideal for customers who are familiar with the design, integration, and handling of electronic components.

Telaire T6615 | Dual Channel CO2 Sensor Module

Telaire T6615 is a Dual Channel CO2 Sensor Module designed to integrate into existing controls and equipment for use in instumentation and applications up to 50,000 ppm. Dual channels consist of one CO2 channel that measures gas concentration and one reference channel that measures the sensor signal intensity.

Carbon Dioxide (CO2) Transmitters

Telaire T3000 Series | CO2 Sensors for Harsh Environments

Telaire T3000 Series is a range of Carbon Dioxide (CO2) Sensors designed to meet the specific needs of customers who require measuring CO2 in harsh or difficult environments. Based on a series of modules, the casing offers a number of combinations to meet the needs of range, supply voltage, and output type in various applications. Example applications include incubators, buses, refrigerators, subway stations, and railway carriages.

Telaire T3030 Series | CO2 Sensors for Harsh Environments with Analog Outputs

Telaire T3030 Series is a range of Carbon Dioxide (CO2) Sensors designed to meet the specific needs of customers who require measuring CO2 in harsh or difficult environments. Based on a series of modules, the casing offers a number of combinations to meet the needs of range, supply voltage, and output type in various applications.

Telaire T3022 Series | IP65 CO2 Sensors for OEM Installation

Telaire T3022 Series CO2 Sensor is designed to meet the needs of OEM manufacturers for low cost Carbon Dioxide (CO2) sensor installations by providing reliable and convenient CO2 measurement in an IP65-rated enclosure.

Telaire T8000-R Series | Wall Mount CO2 & Temperature Transmitter

Telaire T8000-R Series of Wall Mount CO2 and Temperature Transmitters consists of low cost, high performance CO2 and temperature transmitters with relay for building controls and indoor growers markets.

Telaire T5100-LED Series | Wall Mount CO2 Transmitter

Telaire T5100-LED Series of Wall Mount CO2 Transmitters offers low cost, high performance CO2 transmitters for the building controls market.

Telaire T5100 Series | Wall Mount CO2 Transmitters

Telaire T5100 Series of Wall Mount CO2 Transmitters offers low cost, high performance CO2 transmitters for the building controls market. It works seamlessly with building automation systems, and allows you to simply and effectively control fresh air. Demand-controlled ventilation using CO2 sensors prevents energy loss from over-ventilation while maintaining indoor air quality.

Telaire T8000 Ventostat | Wall Mount CO2, Humidity & Temperature Transmitters

The Telaire Ventostat 8000 Series represents a full range of wall mount carbon dioxide, humidity and temperature transmitters with display options plus active humidity and temperature outputs. The Telaire 8000 Ventostat Series provides controlled ventilation with easy installation and a clean, modern look that suits most indoor environments.

Telaire T8100 NS/NSP Ventostat | Wall Mount CO2 Sensors

Telaire Ventostat T8100 NS/NSP Series of Wall-Mount CO2 Sensors provide patented, absorption infrared gas sensing with high accuracy in a compact, low cost package.

Telaire T8041/T8042 Ventostat | CO2 Duct Probe Transmitter

Telaire Ventostat T8041/T8042 CO2 Duct Probe Transmitter is suitable for indoor air quality and energy conservation applications, offering accuracy and versatility at an affordable price.

Telaire T8031 Ventostat | CO2 Duct Mount Transmitter

Telaire Ventostat T8031 CO2 Duct Mount Transmitter is the smallest package available designed to be installed in HVAC return air ducts. It is designed for indoor air quality and energy conservation applications, offering accuracy and versatility at an affordable price.

Dust Sensors

Telaire DSF Series | PM2.5 Automotive In-Cabin Particulate Dust Sensor

Telaire DSF Series of PM2.5 Automotive In-Cabin Particulate Dust Sensors are designed specifically to meet the needs of OEM manufacturers for a low cost dust sensor with Lin2.2 Output for in-bulkhead mounting.

Humidity Sensors

Telaire T9602 | IP67 Harsh Environment Humidity & Temperature Sensor

Telaire T9602 IP67 Harsh Environment Humidity & Temperature Sensor is a fully-calibrated and temperature-compensated combined humidity and temperature sensor supplied in a water-resistant IP67 package, making it the most advanced and cost-effective sensing solution for virtually any type of harsh environment application.

Telaire HS12SP | Relative Humidity Sensor

Telaire HS12SP is a bulk-resistance type of Relative Humidity (RH) Sensor providing a variable impedance value in response to the adsorbed water within the sensor’s proprietary thin-film polymer.

Telaire HS20 | Relative Humidity Sensor

Telaire HS20 is a bulk-resistance type of Relative Humidity (RH) Sensor providing a variable impedance value in response to the adsorbed water within the sensor’s proprietary thin-film polymer.

Telaire ChipCap 2 | Humidity and Temperature Sensor

The Telaire ChipCap 2 offers the most advanced and cost effective humidity and temperature sensing solution for virtually any type of application.

Telaire ChipCap 2-SIP | Humidity and Temperature Sensor

Telaire ChipCap 2-SIP is a Single In-line Package (SIP) type of ChipCap with ready installed V-core capacitor for easy and convenient application. Individually calibrated and tested, ChipCap 2-SIP performs ±2% from 20% to 80%RH (±3% over entire humidity range), and yet is simple and ready to use without further calibration or temperature compensation.

Telaire HS30P | Relative Humidity Sensor

Telaire HS30P is a bulk-resistance type of Relative Humidity (RH) Sensor providing a variable impedance value in response to the adsorbed water within the sensor’s proprietary thin-film polymer.

Humidity Transmitters

TELAIRE T8700 | Relative Humidity & Temperature Transmitter

Telaire T8700 | T8700 is a precision humidity and temperature transmitter for HVAC control applications that uses Amphenol Advanced Sensors own ChipCap Sensor, allowing for quick and simple field replacement, negating the need to replace or return the complete transmitter for recalibration.

Telaire EHRH | Waterproof Relative Humidity Transmitter

Telaire EHRH Relative Humidity Transmitter is a waterproof RH sensing element and package, which is ideally suited for monitoring relative humidity in high RH/harsh environment applications or where washdowns are required. The unit is designed for continuous monitoring of relative humidity and temperature and is available in ±2% accuracy.

Telaire RH/RHT Series | Relative Humidity & Temperature Transmitters

Telaire RH/RHT Series of Relative Humidity (RH) and Temperature Transmitters are designed for continuous monitoring of relative humidity (RH) or relative humidity and temperature (RHT). They provide accurate and reliable measurement for building automation and environmental control systems.

Telaire HumiTrac XR | DEWPOINT, ENTHALPY, OR WET-BULB TRANSMITTER

Telaire Humitrac XR Relative Humidity & Temperature Transmitter is an enthalpy, dewpoint, or wet-bulb transmitter range designed for use in HVAC applications. All HumiTrac models incorporate a NIST traceable, field-replaceable sensor tip, a rugged capacitive sensing element capable of full-scale 0 to 100% RH measurement and a host of field configurable output options.

Telaire HumiTrac | Relative Humidity and Temperature Transmitter

Telaire HumiTrac™ Relative Humidity & Temperature Transmitter is Telaire's next generation relative humidity and temperature transmitter, designed to serve the building automation/HVAC market, as well as a wide variety of general purpose relative humidity monitoring applications. All HumiTrac models incorporate a NIST traceable, field-replaceable sensor tip, a rugged capacitive sensing element capable of full-scale 0 to 100% RH measurement and a host of field configurable output options.

Telaire T9501 | Humidity & Temperature Sensor

Telaire T9501 Humidity & Temperature Sensor provides cost-effective humidity and temperature sensing via MODBUS communication protocol for virtually any type of application. Designed to withstand challenging environments, the IP67 rated transmitter utilizes an individually calibrated and tested ChipCap 2 sensor and is ready to integrate into control/monitoring systems without further calibration or temperature compensation.

VOC

Telaire MiCS-VZ-89TE | Integrated VOC Sensor Module

The Telaire MiCS-VZ-89TE Integrated Sensor Module combines state-of-the-art MOS sensor technology with intelligent detection algorithms to monitor tVOCs and CO2 equivalent variations in confined spaces.

Accessories

Telaire T1508 | Aspiration Box Enclosure

Telaire T1508 Aspiration Box Enclosure is designed for in-duct sampling of CO2 concentrations at flow rates greater than 400 fpm. Clear cover allows for observation of the sensor. Compatible with all Ventostat 8000 Series and Vaporstat 9002 Models.

Telaire T2076NG | Calibration Kit

Telaire T2076NG Calibration Kit includes all components necessary to allow for simple and quick calibration of specific Telaire sensor models. For use with Vaporstat 9002.

Telaire T1505 | Splash Resistant Enclosure

Telaire T1505 Splash Resistant Enclosure is designed to protect the sensor in damp or wet environments which might occur in agricultural, industrial or food processing environments. This enclosure (ABS plastic) is designed to protect the sensor from dripping or sprayed water. The transparent cover allows for viewing of the sensor/display. Compatible with all Ventostat 8000 Series and Vaporstat 9002 Models.

Telaire T1551 | Outside Air Enclosure

Telaire T1551 Outside Air Enclosure is a rugged weatherproof enclosure (ABS plastic), designed to allow the Telaire T8000 Series to operate in an outdoor environment and/or where ambient temperatures are below freezing. T1551 is ideal for monitoring outside air or CO2 as a surrogate for combustion fumes in parking garages, tunnels and loading docks. This enclosure features a temperature control circuit and internal heaters to maintain the sensor within its normal operating temperature range. Enclosure is designed to screw directly to a wall. Compatible with all Ventostat 8000 Series Models.

Telaire T2090 | Calibration Software

Telaire T2090 Ventostat UIP Calibration Software allows you to modify the standard settings on the T8100, T8200 and T8300 Series products. The software can be used by distributors to make modifications to the Ventostat prior to shipping to the customer, as well as to make adjustments in the field.

Telaire T1552 | Outside Air Enclosure

Telaire T1552 Outside Air Enclosure is a rugged weatherproof enclosure (ABS plastic), designed to allow the Telaire T8000 Series to operate in an outdoor environment and/or where ambient temperatures are below freezing. T1551 is ideal for monitoring outside air or CO2 as a surrogate for combustion fumes in parking garages, tunnels and loading docks. This enclosure features a temperature control circuit and internal heaters to maintain the sensor within its normal operating temperature range. Enclosure is designed to screw directly to a wall. Compatible with Telaire T8000 Series Models (T8100, T8200, T8300).

Pressure Transmitters

Modus HVAC Differential Pressure Transmitters | W Series

Modus W Series of HVAC Differential Pressure Transmitters are designed to measure low differential pressures of liquids or gases. A wide selection of standard pressure ranges and electrical ratings is available. These transmitters are an excellent choice for many HVAC, process and automation monitoring requirements.

Modus HVAC Differential Pressure Transmitters | T Series

Modus T Series of Differential Pressure Transmitters measure low pressures and feature low power consumption with a variety of analog signal outputs. A wide selection of standard pressure ranges and electrical ratings is available. These transmitters are an excellent choice for many HVAC, process and automation monitoring requirements.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)